In-house engineering at ProDirectional

Engineering expertise at our fingertips makes all the difference.

Our engineers have a hand in everything we do

Unlike many other service providers, ProDirectional has a large in-house engineering department with skilled team members who create value for our clients every step of the way. Drilling better wells is our ultimate goal, and here’s how our engineers ensure we exceed our clients’ expectations.

ProDirectional Engineers

Mechanical and electrical engineers

Instead of buying all of our drilling motor and MWD equipment from third-party providers and using it as is in the field, we put our mechanical and electrical engineers to work so they can develop new and more effective products compared to what exists on the market today. They look at the common issues that arise with third-party equipment, conduct root cause analyses for failure, and address the problems to create enhanced tools you can’t find elsewhere on the market. Our mechanical and electrical engineers are responsible for product development so we can provide our clients with top-of-the-line technology.

Application engineers

The value of an application engineer is to help understand and optimize performance. We have a broad range of MWD tools and drilling motor offerings, and our application engineering team works to understand the client’s needs and then recommend tools and operating parameters that enhance performance while mitigating risk. The strategists of our team, the in-house application engineers are experts in solving complex drilling problems with industry-leading drilling solutions that are developed by our mechanical and electrical engineers.

Software engineers

At ProDirectional, we put a lot of importance on collecting the right data at the right time. Our software engineers develop proprietary software that enables us to collect data on all of our equipment so that we know exactly how it is used, what repairs it has had, and when it needs to be retired. They also develop systems to track and optimize operational timelines so that we can better support our clients in meeting their drilling schedules. Our software engineers ensure that we’re never flying blind on any project — they help us get unparalleled insight to make better decisions that impact our clients’ performance.

Our in-house engineers speak your language

Whether you want to discuss proprietary equipment, solutions for challenging applications, or something else, get in touch with us today.

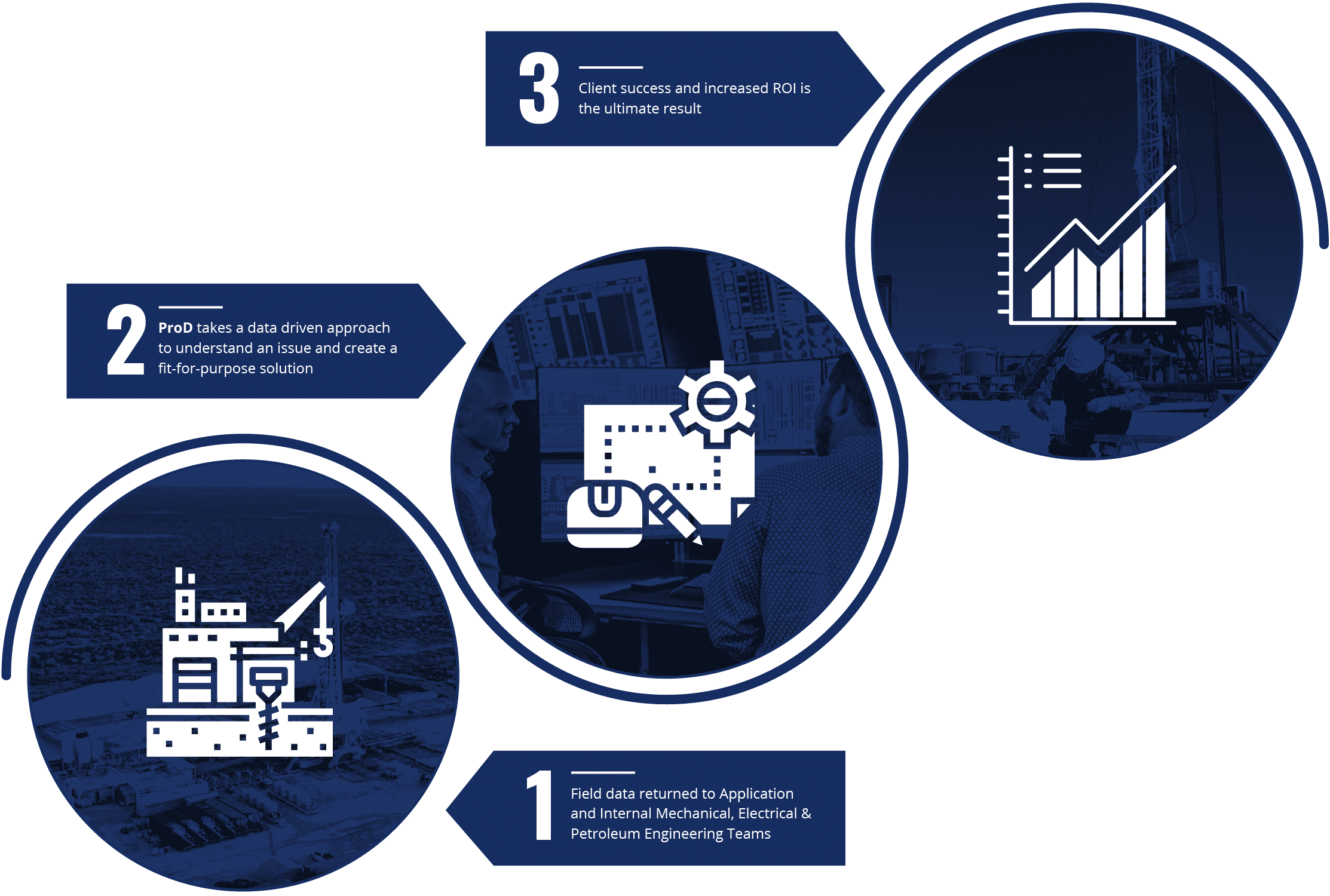

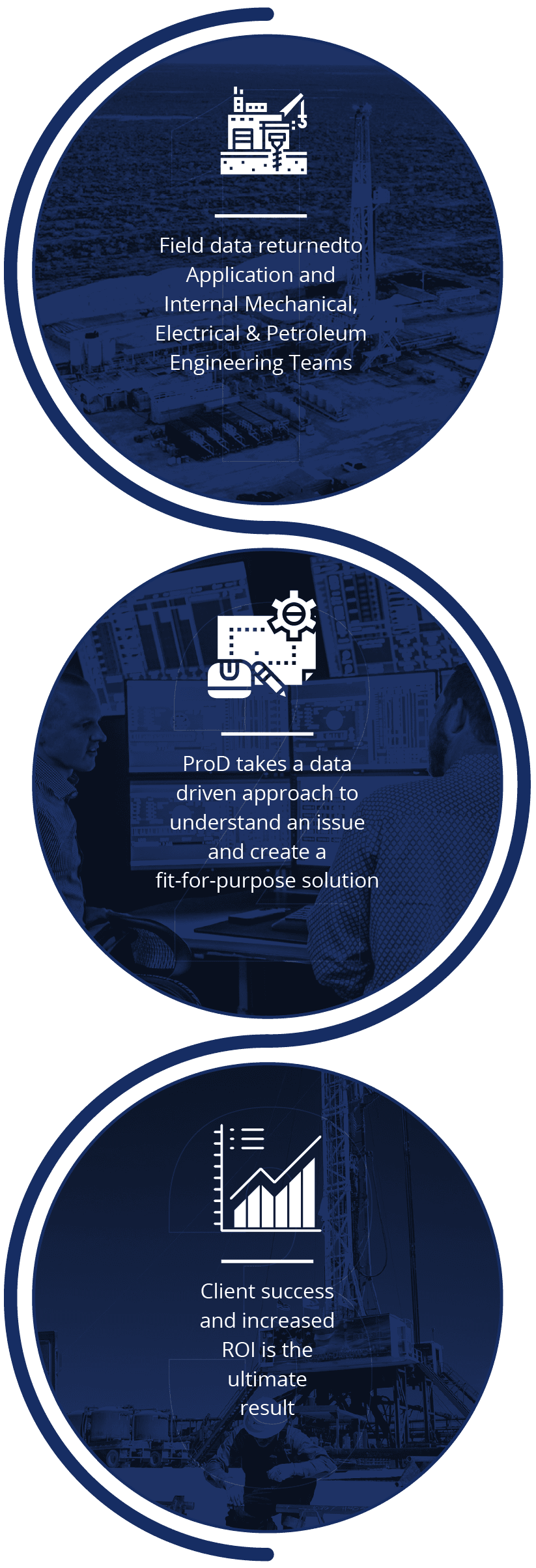

The engineering workflow

Collecting field data:

At every job, our team collects a large amount of data from the site. Our mechanical, electrical, and application engineers analyze the information to better understand any challenges and issues that arise. We also review what worked well and what can be repeated for consistent results.

Implementing expertise:

Based on the data collected, the mechanical and electrical engineers make enhancements to our equipment and processes so that we can create a fit-for-purpose solution for our clients designed by our application engineers.

Exceeding expectations:

Better return-on-investment, improved timelines, enhanced performance — our data-driven approach leads to stellar results for our clients. We repeat this process for every job so that we are continually improving our outcomes.

Why is it important to work with a service provider that has a large in-house engineering team?

When you put your well in the hands of our engineers, you get peace of mind — and unprecedented results

Contact ProDirectional today to learn more about our engineering expertise and how it can enhance your next drilling project.