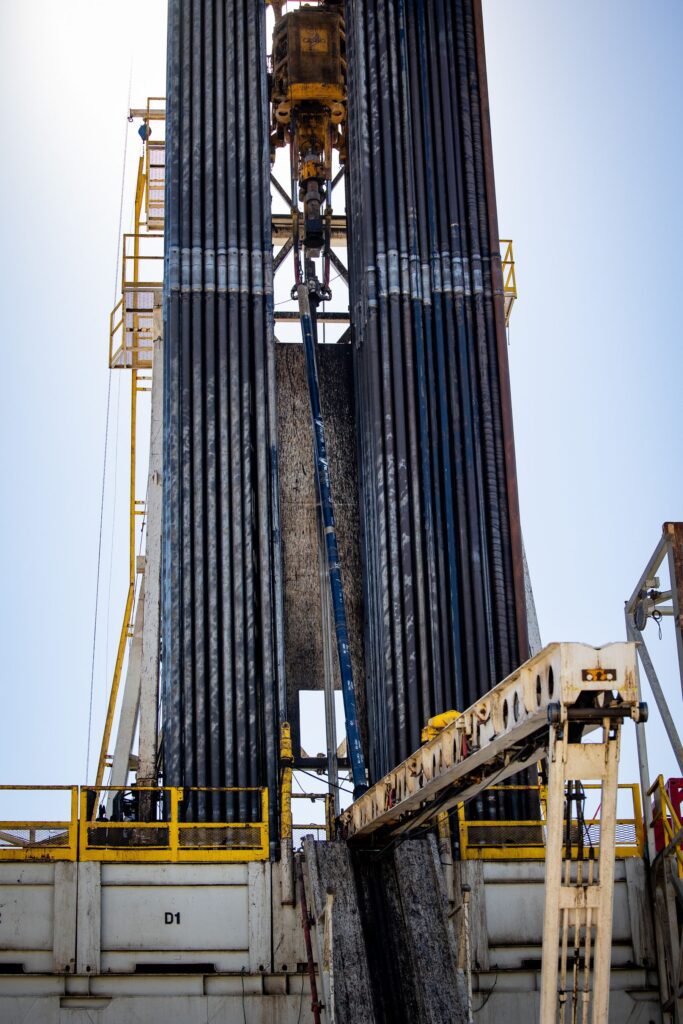

Highly customized MWD equipment and mud motors get the job done

If you consider the different basins and geographical areas in the continental United States, there is a lot of diversity in the formation, well construction requirements, and reservoir temperatures. That means that the way you drill wells in these different basins needs to be diverse also — you cannot use the same MWD tools and mud motor technology in the Permian as in the Haynesville because you’re dealing with a completely different application.

That’s why when you’re considering which MWD and directional drilling service provider to work with, it’s important to look at their diversification of technology and skill. If they can’t offer a way to customize the drilling equipment based on the characteristics of your specific application, you may end up in a situation where you’re dealing with non-productive time as a result of downhole equipment issues — costing you a lot of time and money.

At ProDirectional, we pride ourselves on our ability to adapt to any drilling situation. We understand how important it is for our clients to avoid NPT, so we come prepared with the right tools for the task at hand.

MWD services and mud motors for the oil and gas industry

We are experienced in drilling in every major basin across the United States, from the Eagle Ford Basin to the Permian or Haynesville, and a multitude of others. With this kind of diverse experience, we have had the opportunity to develop the range of drilling equipment required for each type of geographical area.

Mud motors for directional drilling

We offer our customers over 30 different types of directional motor configurations — far more than the typical directional drilling service provider on the market. Our application engineers carefully select the downhole motor configurations our customers need by evaluating the different formations and temperatures we have to drill through, resulting in a job that remains on schedule and maximizes efficiency.

Measurement while drilling (MWD) tools

Not only that, but we also have four different MWD equipment platforms — Sprint MWD, Octane MWD, Octane XT MWD, and Electromagnetic MWD — allowing us the ability to accurately, safely, and successfully drill in any area regardless of the challenges our clients are facing.

We don’t try to force fit generic technology for every application. Instead, we customize the drilling motor and MWD tools to meet our customers’ unique needs on location.

Drilling with mud motors and MWD technology that’s fit for purpose

Our application engineers and operational teams recommend which MWD equipment and mud motors our customers should use based on the unique characteristics of each basin.

- Eagle Ford Basin: In this area of Texas, speed is a driving factor. It’s important to choose powerful equipment that can drill quickly and efficiently. In addition, downhole temperatures can be elevated in this region, so it’s important to have equipment that can withstand extreme heat while performing reliably.

- Permian Basin: In this region, there are a multitude of target formations that are produced, so one of its unique characteristics is the diversity itself. We have a range of downhole drilling equipment that can be customized to meet the needs of each benchmark in the Permian — that goes for both the Midland and the Delaware basins.

- Haynesville: Temperature is an important factor here because it gets extremely hot in this harsh drilling environment. This area also requires equipment that is going to be highly reliable — because if an issue occurs in the production interval, it can take a day or more to get back into the hole. We always aim for some speed here; but we really focus on going for reliability to lower well costs.

- Marcellus and Utica: In these regions, we frequently drill on air. Here we utilize electromagnetic (EM) MWD tools for the right results. Plus, we’re dealing with extremely long extended reach laterals, which require highly specialized knowledge and capabilities.

- Powder River and the Rockies: In these areas, the drilling applications vary a lot, and there are also challenges around getting the MWD equipment and steerable motors where they need to be on time, especially in the winter months. This requires a regional presence as well as specialized logistical and operational experience along with proper job planning.

Pivoting with downhole drilling tools and steerable motors

Across the board, ProDirectional has the most diverse asset base which we can customize according to the needs of the many different applications clients have. What this also means is that we have the ability to pivot faster than other service providers.

For example, if we encounter an unexpected issue while drilling that requires a different type of mud motor or MWD tool — in any basin — we have the technology available in house we can deploy right away, minimizing NPT for our customers.

Unrivaled expertise in downhole mud motor design and MWD tools

Having the ability to offer customized MWD equipment and mud motor tools is one thing; you need the application engineering expertise to oversee it. That’s why we have an application engineering team that supports each of the different regions we operate in, with dedicated personnel for key basins. In addition, we also have operational teams to support each basin, along with our well planning team.

Our experts become specialists in their areas by focusing their time and effort on the unique characteristics of the location and the challenges that can arise because of them. This helps us to be ready with solutions that we can apply whenever a problem emerges, saving our customers time and money.

Supporting our application engineers, operational teams, and well planning teams is our Remote Operations Center, which consists of highly experienced personnel that have knowledge of all the major basins. They are available 24/7/365 to provide guidance on any issues that occur.

You need the right MWD tools and downhole motors for the job

Don’t settle for service providers that want to jam a square peg in a round hole. You simply can’t achieve the results you want by using generic technology for specific applications. Reduce non-productive time and increase performance — while saving your time and money — by choosing fit-for-purpose technology that is highly customized for your application and managed by personnel with specialized knowledge.

Get in touch with ProDirectional today to discuss the specific characteristics of your drilling application.